In the meantime, I sourced an old stock 3G alternator, rusted from sitting in someone's shed, and one that was on a running car that is known good. I also still had my original in the car. Once the remanufactured alternator arrived, I had a total of four 3G alternators.

The remanufactured units don't come with a pulley. The two alternators that I sourced did have pulleys. One was stock, the other one is an underdrive. I also still have the stock one on the one in the car. I removed the stock pulley from the unit that was sitting in the shed. I cleaned it up the best I could and hit it with some self etching primer followed by some engine enamel. It was better than before, but didn't look all too great. I realized at this point that I was going to need a media blast cabinet to do some clean up work. More on that in another post!

I removed the stock 245k mile alternator again (I've had practice). I installed the pulley I had just painted on the Remanufactured unit and installed it in the car. That entire process took about 25 minutes. Next step was to take it for a ride and see if the voltage drop was still present. I started it up to make sure everything was working as expected and noticed the voltage gauge on the dash read higher than it usually does. This was a good sign! I shut the car down.

Next I boxed up the rusted old alternator as a core return, got the label on the box and brought it to the FedEx drop off. After it arrived at Rock Auto, they inspected it and returned to me the 75$ core charge. Nothing like getting 75 for an alternator that doesn't really work, is rusted and I don't know how many years old. This also meant that I was into the remanufactured Motorcraft that is installed in the car for 106$ total.

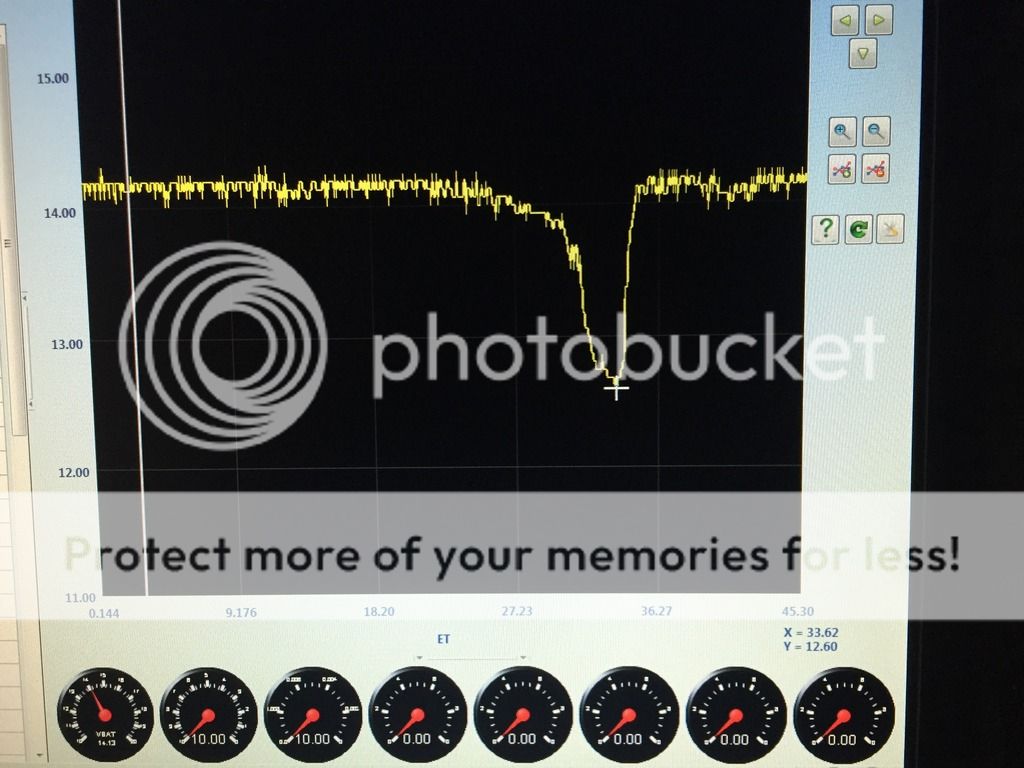

I took the car for a ride and eventually wound up at the same hill where I do my testing and logging. I did the same exact thing that produced the last few logs that showed the voltage drop. Once I got back to the house, I checked the log. Its FIXED! The minimum voltage was 14.18. Much better!

I still may upgrade to a 200A alternator. The way I figure, and since I have another core to use, it would cost me out of pocket significantly less than buying a 200A off the shelf. All I need is the remanufactured unit, an upgraded rectifier and an upgraded stator. Maybe a winter project once my bank account recovers!!!